Custom Bushcraft Knife Options

About this page. This guide is designed to help you learn more about our bushcraft knives and knife options.

Index:

1A - What is a custom knife?

In short a custom knife is a knife where the customer is allowed to choose different options associated with the build of the knife. Custom knives go beyond just choosing a color; they often have many options, in our case it includes handle materials used, liners used, the hardware and metal used, the appearance of the blade. It often even includes options that allow the customer to choose their type of steel and cutting edge "grind", affecting the performance of the knife to better suit their intended purposes.

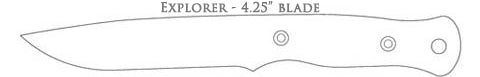

Currently we are only taking custom orders for one model at a time, and right now that model is the Explorer. Click this link for more information.

Bushcraft is practiced and implemented by any outdoorsmen; campers, backpackers, fishermen, hunters, explorers, etc., but of course it originated in the most primal era of human existence.

Example bushcraft skills include; whittling wood, splitting wood, fire making, shelter building, camp furniture building, tool creation (wooden tent stakes, walking sticks, pot suspension rigs, spoons, etc.), building natural boats/rafts, wild plant foraging, primitive navigation, tracking, fishing, hunting, trapping, weather forecasting, and the list goes on

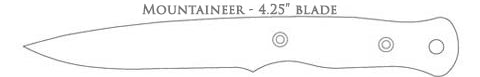

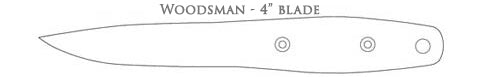

2 - Choosing a knife model

Being dominantly a bushcraft knife company, most of our knife models are geared towards bushcraft use. Therefore, our knives are versatile enough to handle whatever you would throw at it in the wilderness. Some knives are designed for versatility, while other models have a more specific task in mind. Click a model below to be brought to it's page

Bird & Trout and Camp Kitchen Bushcraft Knives

Lightweight and Compact Bushcraft Knives

3 - Blade steel type

We offer three different steel types; O1 high carbon tool steel, CPM 3V high toughness alloy tool steel, and CPM S35VN stainless alloy steel. It is worth first noting that we only use the best steel in the world for our knives, so regardless of what you choose, you will be happy. Not every model is always available in every steel type.

Quick Guide: Our recommendation is that if you mostly do woodworking with your knife, we suggest O1 tool steel paired with a scandi grind. If you mostly use your knife for things other than woodworking (food prep, hunting, utility tasks like cutting rope, etc.), we recommend CPM 3V steel paired with a convex grind. If rust is a real concern for you, then we recommend using CPM S35VN stainless steel paired with any grind. There are benefits, and unique changes in performance, when you change up the rules, such as placing a scandi on CPM 3V, or a convex on O1. And our customers often do that. But if you're a tad confused, we would recommend sticking to our above guidelines.

O1 tool steel. O1 is considered the 'gold standard' steel for bushcraft use. This steel is renowned for its ability to take a very sharp edge. O1 seems to hold an edge incredibly long - specifically when it is paired up with a scandi grind and used in woodworking tasks (push-cuts and batonning). This has to do with a blend of the chemical makeup of O1 and the fact that it has a very fine grain structure, which lends itself well to the very 'absolute' edge of a scandi. 59 RC hardness

CPM 3V. This steel's primary advantage is that is has high toughness. Basically 'toughness" covers shock absorption and unlikeliness to chip or break. It is also very abrasion resistant, and very rust resistant (between O1 and S35VN). It holds an edge very well, but is also the hardest to sharpen. The toughness of CPM 3V is mostly taken advantage of when used with thinner edge geometries, such as convex or flat grinds. 60-61 RC hardness

CPM S35VN. This is one of the only, if not the only, steels designed specifically for use on high-end knives. This is our new stainless option, and damn does it make a fine knife steel. This steel is recommended for anyone who fears that their knife is going to be extra prone to rusting, such as those who live in very wet environments, or for those who simply don't want to have to worry about corrosion. 60-61 RC hardness

4 - Blade Thickness

Quick Guide: We only offer one blade thickness for each model.

Occasionally certain models are offered in multiple blade thicknesses. Basically a thinner steel is lighter and will slice and carve better. A thicker steel is tougher and will split wood and chop better.

We have recently been dialing back on blade thickness options, allowing customers only one thickness selection - the one which we recommend for that given model. We may offer thickness options in the future, but we are unsure at this time.

5 - Blade Edge Grind

The two most popular edge grind styles for use in bushcraft are scandi and convex. We also offer flat grinds with a secondary bevel. Not every model is offered with both options

Quick Guide: Scandi grinds are better at woodworking. Convex grinds are better at everything else. A flat grind performs most similar to a convex.

Scandi grinds are short, flat, single-bevel grinds, which primarily excel in woodworking tasks; wood power-cuts, fine whittling, and splitting wood via batonning. The majority of what most people do in bushcraft is woodworking, hence the popularity of the scandi grind. Because the stock blade thickness runs through the majority of the blade, scandi grinds are very tough and break-resistant. The short, wedge-shaped grind has a pronounced shoulder, which helps split wood apart when batonning, but also makes it perform worse at slicing oriented chores (such as food / meat prep).

Convex grinds are thin, full-height grinds, which are dominantly flat and gradually get steeper towards the cutting edge. Convex grinds primarily excel in slicing oriented tasks; meat & food prep, filleting fish, cutting rope, etc., and penetrate the deepest when chopping. When it comes to wood carving, most people find that convex grinds are a bit less aggressive and harder to control than a scandi. In our case, however, even our convex grinds are geared towards woodworking more so than your typical convex grind, so that shouldn't be an issue.

Flat grinds are very similar to convex grinds in most regards. The difference is that flat grinds have two pronounced flat bevels; a primary grind, and a secondary grind. A convex grind gradually gets steeper as the edge meets. The benefit of a flat grind is that it slices very well, and it is a very easy grind to sharpen in the field.

8 - Handle Scales

The handle scales are the primary material used for your knife handle. We only offer stable choices, so whether or not you select a synthetic or a natural material you can be sure that your handle is suitable for regular use in bushcraft.

Synthetics are, of course, always going to be tougher and more weather-resistant than naturals. So if you're going to be using a knife which you know will be subjected to water often, a synthetic handle is your best bet.

For an example gallery of handle material options, please visit this link.

10 - Handle Liners

The handle liners are the strips of material which run between the blade steel and the handle scale material. Liners are dominantly a visual preference thing, though they can add a very slight degree of strength by absorbing some of the shock from chopping or batonning (the thicker 1/8 inch liners may provide more shock absorption). The second liner runs between the first liner and the handle scale material, and is purely for aesthetics.

Thin black liner

Thin blue liner with a thin white secondary liner

Example Of Handle Liner Thickness:

11 - Bolts & Tube

Loveless bolts are our hardware, of course because they securely fasten on the handle scales with clamping stability. We currently have two options, brass and aluminum. Brass has a more traditional look, aluminum matches the color of the steel blade better. In terms of performance, they are equal, but aluminum hardware does reduce the weight a bit.

14 - Logo

We have two different logos that may be placed on the knife. The more subtle option is the company name on the spine. The more decorative option is our circular landscape logo to be placed on the satin flats of the knife.

Spine etch (top), Circular landscape logo (bottom)

15 - Matching Firesteel

A firesteel is a metal-blend rod which can be struck to create sparks. A dedicated striker can be used to strike the firesteel, though the spines of our knives are a crisp 90 degree angle for throwing sparks as well. Our matching firesteels are 3 x 3/8 inch long, and the handle is made of material which matches your knife handle.

Note: As of 2020 matching firesteels are ordered separate from the knife. [Visit this link for more information]

16 - Sheath Type

We make handmade custom leather sheaths in our shop for the knife at hand. Our leather sheaths are offered in right or left-handed variations. A right-handed sheath, when worn, will have the direction of the knife edge facing behind you

17 - Sheath Color

We offer three different sheath colors; chestnut brown (a medium brown), dark brown, black, and burgundy.

18 - Sheath Additions

Optional add-on's are available for our custom leather sheaths.

- Firesteel loops are designed to hold a 3/8 diameter firesteel or sharpening rod.

- Removable danglers allow your knife to ride lower. This can be helpful if you find that your backpacking hip belt jabs the top of your knife and sheath, and you want it to ride lower to prevent this. The dangler can be added or removed with a simple screw-in pin.

Firesteel loop

Removable dangler

Ready to try build your own custom knife? Visit our Custom Explorer order page and see what combination you can come up with!

Hopefully this guide helped answer any questions about our knives. If you have any specific questions, feel free to Contact Us, and we will get back to you as soon as possible. To view the knives we have for sale check out our Available Knives page. To be notified of upcoming sales, be sure to Subscribe To Our Newsletter.